CREATING THE PERFECT

HEATING ENVIRONMENT.

Plants need water, sunlight, and fertile soil to grow, but they also need ideal temperature conditions to avoid freezing. With the right greenhouse commercial heating systems and solutions from GGS Structures Inc., you can maximize growth and ensure strong and healthy crops throughout the year. Which greenhouse heating system is right for your operation? There are several to choose from, each offering a variety of potential benefits in your greenhouse systems.

Elevate Your Greenhouse Experience with Niagrow: Pioneers in Precision Heating Solutions and Climate Control

Experience professional-grade greenhouse heating solutions with GGS. From inception to success, our dedicated team ensures precision and unmatched comfort. Trust us for tailored heating systems that redefine excellence. Your journey to greenhouse climate control starts here. Ready to transform your commercial heating systems? Contact us today for a consultation and take the first step towards optimal heating solutions.

Biomass

Wood, as a biomass greenhouse energy source, represents a renewable form of energy with significant “untapped” potential. It’s abundant, renewable, local, and an eco-friendly and economical alternative, in addition to any modern gas, oil, or efficient greenhouse heating systems. Biomass can be an effective solution for greenhouse heating, especially in large-scale operations requiring commercial heating systems to maintain optimal growing conditions.

Why Wood Heating?

With fluctuating energy prices and a growing concern for the environment, there has been an increasing demand for renewable and efficient heating systems in recent years. Modern wood heating technology, a key player in biomass greenhouse solutions, is ready for the challenge. Green benefits of biomass:

SUSTAINABLE

CO2-NEUTRAL

ECONOMICAL

HIGH-TECH AND RELIABLE

LOCAL AND INDEPENDENT

What Type Of Wood Can I Use?

Biomass wood heating systems can use a variety of untreated, high-quality wood fuels that vary in heating value, required storage capacity and cost. Which fuel type you choose will largely depend on your storage capacity, system requirements and the availability of the fuel in your area. As the quality of the fuel impacts the efficiency and life expectancy of your system, it is best to choose a good-quality, untreated wood fuel with low water content.

Pellets

Sawdust

Woodchips

Mixed Woods

How Economical Is It?

Choosing a high-efficiency wood-fired boiler that uses high-quality, cost-efficient wood fuel is key in optimizing your efficient heating system.

Compared to traditional fossil fuels, the average cost per heat unit of wood fuel is significantly lower in most areas within North America. While the investment cost of a biomass greenhouse heating system may in many cases be higher than a conventional heating system, the fuel cost savings per unit of heat can offset the investment in a relatively short time frame – in a biomass greenhouse heating system, the fuel cost is an estimated 50% of the total lifecycle cost, making your biomass system as economical or better than a fossil fuel heating system. Plus, with a fuel source that is local and independent, your fuel cost is less volatile than with traditional fuels, enhancing the efficiency and cost-effectiveness of biomass heating systems in greenhouses.

Is It Safe?

In a biomass greenhouse heating system, the fuel cost is an estimated 50% of the total lifecycle cost. Choosing a high-efficiency wood-fired boiler and high-quality, cost-efficient wood fuel is key in optimizing the economy of your efficient heating system.

Compared to traditional fossil fuels, the average cost per heat unit of wood fuel is significantly lower in most areas in North America. While the investment cost of a biomass system, including greenhouse heating systems, may in many cases be higher than a conventional heating system, the fuel cost savings per unit of heat can offset the investment in a relatively short time frame – making your biomass system as economical or better than a fossil fuel heating system. Plus, with a fuel source that is local and independent, your fuel cost is less volatile than with traditional fuels, enhancing the efficiency and cost-effectiveness of heating systems in greenhouses.

Is It Clean-Burning?

Yes! Modern wood and biomass heating systems, when professionally operated and maintained, reach similar emission levels to leading fossil fuel heating systems. Better yet, wood heating is CO2-neutral, making it an efficient and environmentally friendly option for greenhouse heating.

What Applications Can It Be Used For?

Our wood heating systems are ideally suited for commercial and industrial applications, such as schools, hospitals, community heating systems, wood processing plants, and more. They also provide efficient heating solutions for greenhouses, ensuring optimal plant growth conditions. These systems are designed to carry either the entire heating load of your system or the baseload, when combined with an oil-/gas-fired boiler for peak times, offering a flexible and efficient heating solution for various needs.

Gallery

Forcas Pipe

Provides targeted heating directly to the crop where it’s needed most. Less waste equals more energy efficient savings for your greenhouse operation.

- Thin wall steel tube ideally suited for greenhouse heating systems in greenhouses

- Brings heat directly to the crop where it is most effective Lightweight and practical application

- Narrow diameter 28/35mm pipe greatly reduces volume of water needed

- Provides quick and energy-efficient heating, making it ideal for commercial heating systems

Product Specifications

- A hot dipped galvanized coating to protect against corrosion

- While elastic powder coating for maximum light reflection

- Two size ranges are available 28 & 35mm O.D.

- Typical under gutter heights are 14′ – 24′

- Easy installation – as a wide range of fittings are available

- Adjustable height control of working system in greenhouses

Gallery

In-Floor Heating

Floor heating in greenhouses has become more and more popular over the past decades because of the considerable benefits warm floors can have on greenhouse crops. Greenhouse heating, particularly in-floor heating systems, is desired because it counteracts the heat loss that occurs from a cold concrete surface in the greenhouse; it is also non-obtrusive as it is beneath the growing surface.

Flood Floors

With fluctuating energy prices and a growing concern for the environment, there has been an increasing demand for renewable and efficient heating systems. Modern wood heating technology, a key player in biomass greenhouse solutions, is ready for the challenge. Green benefits of flood floors:

Sustainable

CO2-Neutral

Economical

High-Tech and Reliable

Local and Independent

Advantages of Flood Floor Heating

- Heating zones can be separated providing individual climate control for different crops

- Best option for providing uniform heating to the entire crop

- Heated concrete floor cuts down on condensate on poly roof. This allows more solar energy to pass through poly, which helps to conserve energy.

General Advantages of Flood Floors

- Maximizes growing area by eliminating need for walkways, more plants per square foot

- Long life – lasts as long as the structure

- Labor savings possibilities, use of conveyors, spacing machines, forklifts, bring carts right to growing area

- If not in use, empty areas can double as storage areas or customized workstations

In Ground Heat

These controlled environment agriculture systems are designed with the crop needs top of mind. Warming the root zone directly results in even temperatures and even crop growth. Custom made flexible polyethylene piping can be buried directly in the growing beds as an efficient heating solution. Instead of covering tiwth concrete, a layer of small pea gravel is used to protect the pipe.

The piping is:

- UV resistant

- Resistant to chemicals

- Resistant to low temperatures

This Niagrow design uses 25mm diameter polyethylene pipe loops in the ground for all in-floor heating. The loops are connected to the steel distribution lines for hot water supply and cooler return water. The steel distribution lines are connected to main line piping that receives the hot water from a central boiler system. Due to the proximity of the heating pipe to the roots of the crop, a lower heating temperature is used to provide the entire growing area with even temperatures.

Gallery

Overhead Heating

Overhead heating is important in areas that get seasons with cold nighttime temperatures. It provides the supplementary heating required to combat these cooler temperatures. While providing additional heat for these cooler months, the overhead greenhouse heating system can also be integrated for use with hanging basket systems and monorail and bi-rail cart setups.

An overhead system with snow melt protection is the perfect solution for northern climates that get accumulated snowfall. A snowmelt protection system can be included as part of the greenhouse heating systems, ensuring efficient heat distribution.

A dedicated snowmelt system can also be designed. This is especially beneficial in greenhouses that have energy curtains. A dedicated snowmelt system sits above the energy curtain, allowing the curtain to remain closed while the commercial heating systems operate, conserving the energy being saved below the curtain.

Perimeter Heating

Perimeter Heating Systems should always be used in cold weather climates in order to protect plants growing near side and end walls. A well-designed Perimeter Heating System provides supplemental heat along the sidewalls, contributing to a uniform thermal environment throughout the greenhouse. Greenhouse heating is essential for maintaining optimal plant growth, especially in colder regions.

Niagrow designs the perimeter heat in consideration with your complete system needs. Greenhouse heating systems, including perimeter heating, can be integrated into existing zone controls or can be controlled as a stand-alone system if extra perimeter heat is desired at night when a heat retention curtain is in use. These commercial heating systems help ensure consistent temperature distribution and energy efficiency.

All our steel heating tube is electric resistant weld tested and certified to ensure maximum life and a leak-free system. Hot Dipped Galvanized hangers are sized for the tubing needed and fasten easily to structure sidewall and end wall posts.

Specific products you may be interested in:

- Hot Water Steel Pipe

- Pipe Hangers

- Pipe Fittings

Under Bench Heating

Under bench heating Systems maintain uniform temperatures and positively affect the microclimate of plants. Greenhouse heating solutions like these ensure efficient heat distribution. Air movement caused by the warmer under bench pipe reduces the humidity around the plant, making it an effective component of greenhouse heating systems. Such systems are suitable for plants grown on benches, fixed tables, rolling, or transportable tables, making them an ideal option for commercial heating systems in greenhouses.

Learn More

An under-bench heating system can reduce fuel costs by 10% or more. Air temperature in the greenhouse can be 5-10 degrees lower than the growing medium temperature and still achieve excellent growth. This lower air temperature means that the heat loss between the inside of the greenhouse and outside will be reduced.

Uniform temperature in the root zone is difficult to achieve with unit heaters that circulate heat over the top of the crop or a boiler that pumps water through fin radiation along the sidewalls. Distributing the heat under the benches warms the growing medium first before it rises to heat the air. For most crops, the medium temperature is more critical to good growth than the air temperature.

Depending on the width of the benches or containers, we design under bench systems accordingly using loops of steel pipe or forcas tubing if preferred. The heating pipe can either be supported on the ground by rose-pin style supports, or by hanging from the bench itself.

Fire Box Boilers

Niagrow is constantly in touch with the needs of the commercial greenhouse industry and can offer a high level of flexibility in design to match the best product to the application. The wetback “firebox” high mass boiler is ideal for greenhouse heating applications; they offer excellent combustion efficiency, compact size, simple design, and reliable serviceability. These greenhouse heating systems are designed to provide efficient and consistent heat distribution, ensuring optimal growing conditions.

- Available with gas, oil, or multi-fuel burners.

- Each boiler is built to exacting quality standards and test-fired before shipping

- Most cost-efficient boiler design with low-cost replacement parts mean lasting cost-efficiency to your operation

- Compact design, will fit where other designs of similar capacities cannot

- Easy to clean and maintain, no special knowledge or skill required

Fire Tube Boiler

Niagrow can provide fire-tube boilers for various applications, including greenhouse heating and commercial heating systems. A fire-tube boiler is a cylindrical high mass pressure vessel where hot flue gases pass through many small diameter tubes set within a tank of water. These hot gases transfer the heat through the walls of the tubes into the water, making them an efficient choice for greenhouse heating systems.

- Easy to clean and maintain

- Tube replacement is straightforward

- Relatively compact

- One unit can provide up to 1500 BHP (47,588,000 Btu/hr)

- Vessel can hold a large amount of water, allowing boiler to respond to load changes with minimum pressure variation

High Efficiency Condensing Boiler

Greenhouse producers of all sizes will benefit from the high thermal efficiency of a condensing boiler while maximizing growing space. Greenhouse heating systems utilizing condensing boilers increase heating efficiency by reducing energy costs and saving growing space in the process.

- 99% thermal efficiency compared to 80% of firebox boiler

- Fully modulating 5:1 turndown with the ability to fire as low as 20% up to 100% maximum output to perfectly meet the heating load

- Up to 100% maximum output to perfectly meet the heating load

- Variable speed boiler pump for perfect control and efficiency

- Small lightweight design

- Easy to use color touch display

- No need to protect against boiler shock, means a simplified hydronic loop (cost savings)

- Multiple units can be staged together to increase output up to an available 350 BHP

Learn More

Investing up front in a condensing boiler will result in more long-term savings. Condensing boilers typically cost up to 50% more than conventional options. However, the payback from 99% thermal efficiency and reduction in fuel use is expected to provide a rapid ROI in less than 5 years. Operating costs for medium an large size heating systems aren’t often given due consideration. By modernizing the heating boilers, energy consumption and environmental impact can be reduced considerably.

Growers adopting high-efficiency options like condensing boilers may be eligible for grants or loans through the Rural Energy for America Program (REAP) and the Environmental Quality Incentives Program (EQIP).

Carbon Dioxide (CO2) Dosing

Carbon dioxide (CO2) is an important element for plants. Carbon deficiency becomes a problem in tight and closed greenhouse environments during daytime hours when photosynthesis occurs, especially when optimizing greenhouse heating systems for plant growth.

The only solution is CO2 supplementation. Central dosage of CO2-rich flue gasses from gas-burning boilers, often integrated with greenhouse heating, has led to a considerable production increase in greenhouse horticulture. Utilizing commercial heating systems ensures efficient CO2 distribution while maintaining optimal growing conditions.

Learn More

- CO2 dosing improves plant growth and vigor

- Increases crop yield and can reduce heating costs

- Flue gas from natural gas-fired burners is very suitable for CO2 dosing

- Flue gas condensers increase the efficiency of your boiler dramatically

Flue gas condensers come in many sizes and varieties. A condenser can raise the efficiency of your boiler dramatically. The engineering staff at GGS will include a flue gas condenser in your heating system design to maximize the efficiency of your boilers by taking advantage of the supply of CO2 that your boiler provides.

From the flue gas condenser the CO2 is distributed through the greenhouse with custom piping by a special exhaust fan designed specifically for this purpose.

We also supply an extensive range of materials that form part of a complete CO2 system. Our engineering and design team can calculate the complete network of pipes required for optimal distribution of carbon dioxide throughout the greenhouse.

Condensers

Niagrow can provide flue gas condensers that are unique in their kind. They are the only flue gas condensers that are completely made of stainless steel. These high-quality flue gas condensers are high-efficiency compact segment condensers with a large heated surface. Many greenhouse horticultural companies use multiple boilers, making them an essential part of greenhouse heating solutions.

One condenser can be supplied to service multiple boilers as a so-called combi-condenser. Using a condenser takes advantage of the latent heat stored in the exhaust gases (typically 450 – 650°F) created by the boiler that would normally be wasted up the chimney. The condenser diverts the boiler flue gases, allowing it to heat the cool heating system water, contributing to efficient greenhouse heating systems and commercial heating systems.

Expansion Systems

In a closed loop hydronic system, some suitable means must be supplied to accommodate the expansion of water volume and the added pressure within the greenhouse heating system when heated to normal operating temperatures. Specially designed ASME Code tanks are necessary for this application and should be rated to withstand system pressure and temperature. A wide range of tanks are available. The importance of purchasing the correct size and design of expansion/compression tank is very important.

GGS supplies a closed tank system which utilizes air pressure to control water volume with a bladder, and an open tank system. The open tank system uses a metal tank without a bladder, excess water flows into the tank and is pumped out when the commercial heating system needs it.

Water glass fixtures or gauges are standard on Expansion/Compression tanks and tank mounted low water cut-offs are available, ensuring reliable operation in greenhouse heating systems.

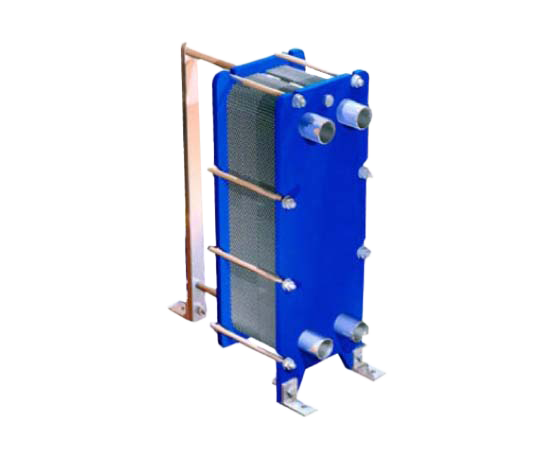

Heat Exchangers

Heat exchangers are used for many different purposes in a greenhouse heating system. Any time you need to heat a water supply with your boiler system but need to keep the two separated, a heat exchanger is the answer.

Some examples are:

- Irrigation water pre-heat

- Heating of growing pools

- Potable hot water for bathrooms and lunchrooms

- Converting steam to a hot water heating system

We provide heat exchangers in three styles, read more about each style below:

Brazed Plate Heat Exchangers:

These are low cost, highly efficient units suitable for all hot water boiler applications. The design of this type of heat exchanger offers higher heat transfer in a smaller package resulting in a more compact unit.

Plate and Frame Heat Exchangers:

Similar in design to the brazed plate units, except that the plates are mounted on a frame and bolted together. These units are expandable by adding or subtracting plates and can be changed to meet the needs of new load requirements.

Shell and Tube Heat Exchangers:

Typically, used when steamis required to supply heat to a hot water system. The heat exchanger consists of an outer shell that contains a series of smaller tubes inside. Steam is fed into the outer shell while cool water is fed into the smaller tubes causing the water to absorb heat.

Pipe Insulation

Considerable fuel is wasted each year from bare greenhouse heating system pipes in areas where heat is not needed. Often in boiler rooms, the main pipe lines from the boilers are not insulated – this represents unnecessary heat loss and can cost the grower valuable energy.

The amount of heat loss from a greenhouse heating system pipe depends on three things: the temperature of the pipe, the diameter of the pipe, and the conditions surrounding the pipe. Basically, the energy loss from the pipe is higher as the temperature within the pipe rises, as the diameter increases, and as the temperature around the pipe gets lower.

To avoid such energy losses, the GGS design team considers this heat loss and insulates where necessary. The insulation used by GGS is 2” – 2.5” covered in an aluminum jacketing. This insulation properly insulates hydronic piping with the aluminum jacketing providing a professional, neat appearance in the commercial heating systems used in greenhouse environments. The jacketing comes with a factory-applied moisture barrier to keep the insulation dry, and it actually reflects the light in the greenhouse rather than taking light away from the plants.

Heat Storage Tanks

A relatively new concept to the greenhouse industry is to use hot water storage with alternate fuel (biomass) heating systems to limit cycling. Greenhouse heating systems, such as wood, burn most efficiently if operated at a constant fire rate. Adding a large, insulated hot water buffer tank can store excess heat during the daytime operation to be used at night when the heat demand is the greatest. This approach enhances greenhouse heating efficiency and supports commercial heating systems in maintaining optimal growing conditions.

Learn More

Heat storage tanks are also common in operations that use their boiler system to generate CO2 during the day. Like the biomass system this hot water is stored for use when CO2 production isn’t required.

Tanks with capacities of up to 1,000,000 litres are available. They are usually steel with an interior liner or anti-rust coating and heavy insulation on the outside. An exterior aluminum jacket protects the insulation. Most tanks are assembled on site.

Design of these systems allows for a smaller boiler as the water storage carries part of the nighttime load. Typical design looks at the maximum heat needs for the coldest day. It also considers the maximum tank water temperature that can be achieved, the lowest water temperature that can be used and the storage period.

In the case of a boiler failure a heat storage tank can supply 12-24 hours of hot water to sustain operation until repairs can be made.

Unit Heaters

GGS can also design greenhouse heating systems to heat your warehouse or greenhouses with unit heaters. We typically use the following units depending on the application. Our greenhouse heating systems ensure optimal temperature control, while our commercial heating systems provide efficient solutions for larger spaces.

Power Vented Unit Heater

Power vented gas fired unit heaters provide 80% thermal efficiency and are available with stainless steel heat exchangers and stainless-steel burners optimum for CEA greenhouse conditions. These units can be vented vertically or horizontally.

High Efficiency Condensing Unit Heater

A conventional unit-heater does not use all available combustion heat. A significant amount of heat is still present in the exhausted flue gases. Condensing unit heaters have a secondary heat exchanger installed to extract extra heat from that flue gas. This allows condensing units to reach 93% efficiency. Available with stainless steel heat exchangers and burners which are optimum for greenhouse conditions. These units can be vented vertically or horizontally.

Hydronic Unit Heater

Hydronic unit heaters are compact and lightweight making them ideal for controlled environment agriculture greenhouse use. These units can use the hot water or steam supplied by the greenhouse boiler system to generate heat. The supply piping can be attached to the top, bottom or the side of the unit allowing for installations in all greenhouses, especially low clearance installations found in older greenhouse structures.

Why Choose GGS?

GGS guarantees customer satisfaction. Featuring a team made up of professionals in the industry, this greenhouse designing, manufacturing, and installing company provides high-quality, long-lasting structures both on-time and on-budget. GGS works with growers of a variety of crops and is committed to delivering structures that help protect and improve the quality of the plant environment.